PET CNC Machining Service

YPMFG's reliable PET CNC machining service producing complex, durable, and smooth-finished plastic parts. Suitable for industrial, consumer, and medical applications.

PETP (Polyethylene Terephthalate) CNC Machining Services

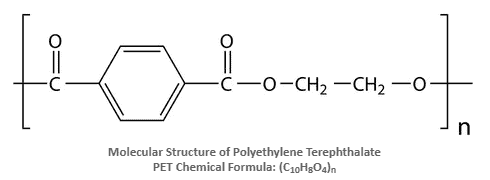

PET CNC machining uses computer-controlled tools to precisely shape polyethylene terephthalate (PET) into complex, high-quality parts. Known for its strength, clarity, low moisture absorption, and chemical resistance, PET is ideal for food packaging, automotive, and medical components. This machining process ensures tight tolerances, smooth finishes, and efficient production, making it a reliable choice for both prototypes and mass manufacturing.

Key Properties of PET-P

- Chemical Resistance

- Enhanced Electrical Properties

- High Dimensional Stability

- High Strength

- Lightweight

- Low Water Absorption

PET Machining Applications

- Food & Beverage Industry: precision parts for bottling machines, conveyor components, and transparent containers.

- Automotive Industry: electrical housings, gears, and durable mechanical parts that require stability under heat and stress.

- Medical & Laboratory Equipment: components such as fluid connectors, test fixtures, and instrument housings thanks to its cleanliness and resistance to chemicals.

- Electronics & Electrical Devices: insulating parts, connectors, and protective covers.

- Industrial Machinery: wear-resistant guides, rollers, and custom mechanical parts.

Material Properties for Machined PET (Polyethylene Terephthalate)

| Material Type | Tensile Strength (MPa) | HDT (°C) | Elastic Modulus (MPa) | Density (g/cm³) | Typical Applications | Notes / Features |

|---|---|---|---|---|---|---|

| PET-GF30 (30% Glass Fiber Reinforced) | 150–175 | 200–220 | 10,000 –10,600 | 1.60–1.65 | Automotive housings, pump parts, mechanical components | High rigidity, excellent dimensional stability, high wear resistance |

| PET-GF15 (15% Glass Fiber Reinforced) | 100–130 | 180–200 | 7,000–8,000 | 1.45–1.50 | Gears, bushings, electrical parts | Balanced strength and machinability |

| Crystalline PET (C-PET) | 80–100 | 80–90 | 3,000–4,000 | 1.35–1.40 | Food containers, chemical tanks, medical parts | Good chemical resistance, food-grade safe |

| PETG (Modified PET with Glycol) | 50–70 | 65–75 | 2,800–3,200 | 1.25–1.28 | Display panels, transparent covers, consumer goods | High clarity, impact-resistant, easy to process |

| Amorphous PET (A-PET) | 60–75 | 75–85 | 2,800–3,200 | 1.33–1.35 | Bottles, containers, optical components | Transparent, low cost, moderate heat resistance |

CNC Machining Resources

How to Tackle Titanium Machining Difficulties

Titanium machining is tough due to heat and wear issues. Find out how to tackle these problems with the right

Metallurgy and Heat Treatment Explained

Comprehensive insights into metallurgy and heat treatment in industrial applications: from crystal structures and iron-carbon phase diagrams to annealing, normalizing,

Comprehensive Guide to Material Properties: 11 Key Differences Between Strength, Stiffness, Hardness, and More

The performance qualities of materials roughly contain strength, stiffness, hardness, deflection, elongation, elasticity, toughness, rigidity and plasticity, etc. This paper