Prototyping is a critical stage in the product development process, bridging the gap between design and production. It allows engineers and designers to evaluate a product’s form, fit, and function before moving into large-scale manufacturing. Today, a wide range of prototyping processes are available, from additive manufacturing methods like SLA, SLS, and DMLS, to subtractive methods such as CNC machining, and even injection molding for pre-production testing.

Each process offers unique advantages in terms of material selection, precision, cost, and production speed. Understanding the strengths and limitations of these technologies helps manufacturers choose the most efficient and cost-effective path from concept to reality.

1. SLA

SLA is an industrial 3D printing or additive manufacturing process that uses a computer-controlled laser to build parts within a pool of UV-curable photopolymer resin. The laser traces and solidifies cross-sections of the part design on the surface of the liquid resin. The cured layer is then lowered to just below the surface of the liquid resin, and the process is repeated. Each newly cured layer bonds to the layer beneath it. This process continues until the part is complete.

Advantages: For concept models, appearance prototypes, and complex designs, SLA can produce parts with intricate geometries and excellent surface finish compared to other additive processes. Costs are competitive, and the technology is available from multiple sources.

Disadvantages: Prototype parts may lack the strength of those made from engineering-grade resins, limiting their use in functional testing. Additionally, parts built within an SLA should be used with minimal UV and humidity exposure to prevent degradation, as they undergo UV cycles to cure their outer surfaces.

2. SLS

In the SLS process, a computer-controlled laser scans from bottom to top across a heated bed of nylon-based powder, gently sintering (fusing) the powder into a solid. After each layer, a roller spreads a fresh layer of powder across the bed’s surface, repeating the process. SLS uses rigid nylon or flexible TPU powder, similar to actual engineering thermoplastics, resulting in parts with higher toughness and precision but rough surfaces lacking fine detail. SLS offers large build volumes, can produce parts with highly complex geometries, and creates durable prototypes.

Advantages: SLS parts are often more accurate and durable than SLA parts. The process can manufacture durable parts with complex geometries, suitable for functional testing.

Disadvantages: Parts exhibit a granular or sandy texture, and resin options are limited.

3. DMLS

DMLS is an additive manufacturing technology capable of producing metal prototypes and functional end-use parts. It employs a laser system to draw atomized metal powder onto the surface. Where drawn, the powder is welded into a solid. After each layer, a blade adds a new layer of powder, repeating the process. DMLS can utilize most alloys, enabling prototypes to achieve full strength and functional hardware made from the same material as production components. When designed with manufacturability in mind, it also holds potential for transitioning to metal injection molding when increased production volumes are required.

Advantages: DMLS utilizes various metals to produce robust prototypes (typically 97% density) suitable for functional testing. Since components are built layer-by-layer, internal features and channels impossible to cast or otherwise machine can be designed. Parts exhibit mechanical properties identical to conventionally formed components.

Disadvantages: Costs may increase when producing multiple DMLS parts. Surface finish is slightly rough due to the powder metal source in direct metal processes. The process itself is relatively slow and typically requires expensive post-processing.

4. FDM

FDM employs an extrusion method to melt and recure thermoplastic resin (ABS, polycarbonate, or ABS/polycarbonate blends) in layers, forming the finished prototype. Because it uses genuine thermoplastic resin, it is stronger than binder jetting and may have limited utility in functional testing.

Advantages: FDM parts are moderately priced, relatively strong, and suitable for certain functional tests. The process can produce parts with complex geometries.

Disadvantages: These parts exhibit poor surface finish with noticeable ripple effects. Compared to SLA or SLS, it is also a slower additive process with limited applicability for functional testing.

5. MJF

MJF uses an inkjet array to selectively apply fusing and refining agents onto layers of nylon powder. Heating elements then fuse these powder layers into solid strata. After each layer, powder is redistributed across the bed surface, repeating the process until the part is complete. Upon build completion, the entire powder bed and enclosed part are transferred to a processing station. There, most loose powder is removed via an integrated vacuum system. The part is then sandblasted to remove any residual powder before reaching the finishing department, where it is dyed black to enhance appearance.

Advantages: MJF is exceptionally fast, producing functional nylon prototypes and end-use production parts in as little as one day. Compared to processes like SLS, final parts exhibit high-quality surface finish, fine feature resolution, and more consistent mechanical properties.

Disadvantages: MJF is currently limited to PA12 nylon. SLS offers superior small feature accuracy (tighter tolerances for fine details).

6. PolyJet

PolyJet uses a print head to spray layer upon layer of UV-curable photopolymer resin. These layers are extremely thin, enabling high-resolution detail. The material is supported by a gel matrix, which is removed after part completion. PolyJet can produce elastic components.

Advantages: This process is moderately priced, can produce prototypes of overmolded parts using flexible and rigid materials, can manufacture parts in multiple colors, and easily replicates complex geometries.

Disadvantages: PolyJet parts have limited strength (comparable to SLA) and are unsuitable for functional testing. While capable of producing complex geometries, PolyJet does not provide insight into a design’s ultimate manufacturability. Additionally, colors exposed to light may yellow over time.

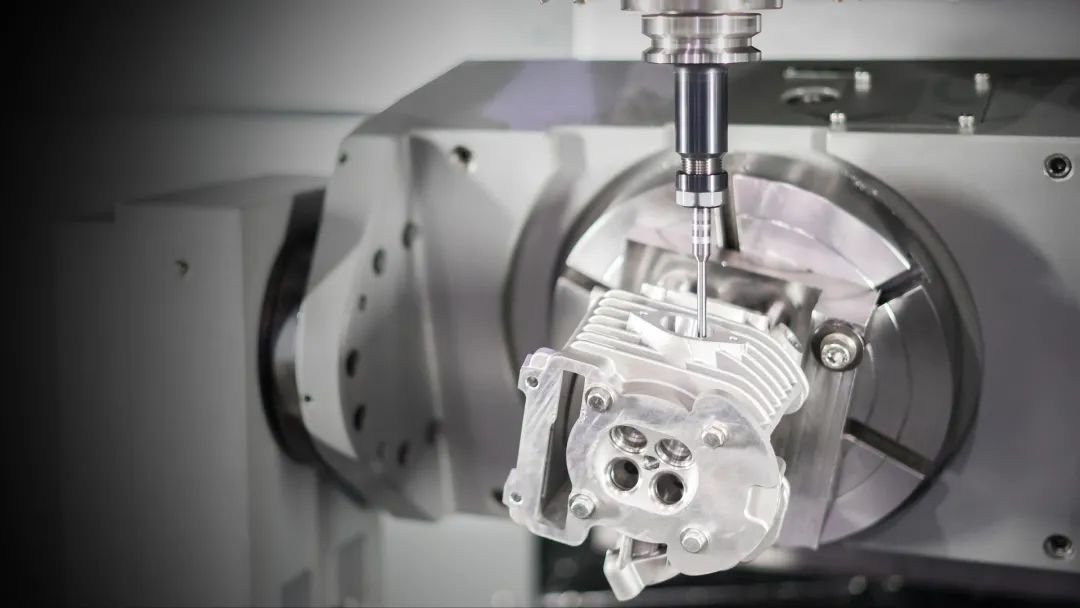

7. CNC

In machining, solid blocks (or rods) of plastic or metal are clamped onto CNC milling machines or lathes respectively, then cut into finished products through subtractive manufacturing. This method typically yields higher strength and surface finish than any additive manufacturing process. It also preserves the integrity and homogeneity of plastics, as it involves machining solid blocks of extruded or compression-molded thermoplastic resin unlike most additive processes that use plastic-like materials and build layer by layer. The material selection range allows parts to possess desired material properties such as tensile strength, impact resistance, heat deflection temperature, chemical resistance, and biocompatibility. Tight tolerances produce parts, fixtures, and jigs suitable for fit and function testing, as well as functional components for end-use applications.

Advantages: Machined parts exhibit excellent surface finish and exceptional strength due to the use of engineering-grade thermoplastics and metals. Like 3D printing, custom prototypes can be delivered within a day by some suppliers.

Disadvantages: CNC machining may impose certain geometric limitations and is sometimes more expensive than 3D printing when performed in-house. Since the process removes material rather than adding it, achieving clean milling undercuts can be challenging.

8. Injection Molding

Rapid injection molding works by injecting thermoplastic resin into a mold, much like production injection molding. What makes the process “rapid” is the technology used to produce the molds, which are typically made of aluminum rather than the traditional steel used for production molds. Molded parts are robust with exceptional surface finish. This is also the industry standard production process for plastic parts, making prototyping within the same process inherently advantageous when feasible. Virtually any engineering-grade plastic or liquid silicone rubber (LSR) can be used, freeing designers from material constraints typical of prototyping processes.

Advantages: Molded parts are produced from a range of engineering-grade materials with excellent surface finish, serving as an excellent predictor of manufacturability for the production stage.

Disadvantages: Initial mold costs associated with rapid injection molding, which do not occur in any additive process or CNC machining. Therefore, in most cases, it makes sense to conduct one or two rounds of rapid prototyping (subtractive or additive) to verify fit and function before proceeding to injection molding.

How to Choose the Right Prototyping Process

Choosing the right prototyping process depends on factors such as material requirements, mechanical strength, surface finish, geometry complexity, and budget. Here are some general guidelines:

- For visual or conceptual prototypes:

Choose SLA or PolyJet, which provide high surface quality and fine details ideal for presentation models. - For functional plastic prototypes:

SLS or MJF deliver durable parts suitable for fit, assembly, and limited functional testing. - For metal prototypes or end-use parts:

DMLS is ideal, offering high-strength, production-grade metal components. - For precision mechanical parts:

CNC machining provides excellent dimensional accuracy and surface finish for both plastic and metal components. - For large-scale production or market-ready parts:

Injection molding is the best option once the design is finalized and verified, ensuring repeatability and production efficiency.

Conclusion

Each prototyping process has unique advantages that support different stages of product development. Additive manufacturing methods like SLA, SLS, and DMLS are perfect for rapid design validation and complex geometries, while CNC machining and injection molding deliver functional, high-precision, and production-ready components.

At YPMFG, we offer a full range of prototyping and manufacturing services from 3D printing to precision CNC machining and rapid injection molding helping you turn ideas into real, manufacturable products quickly and efficiently.

By combining advanced technology with professional engineering support, YPMFG ensures every prototype meets your requirements for accuracy, quality, and performance.