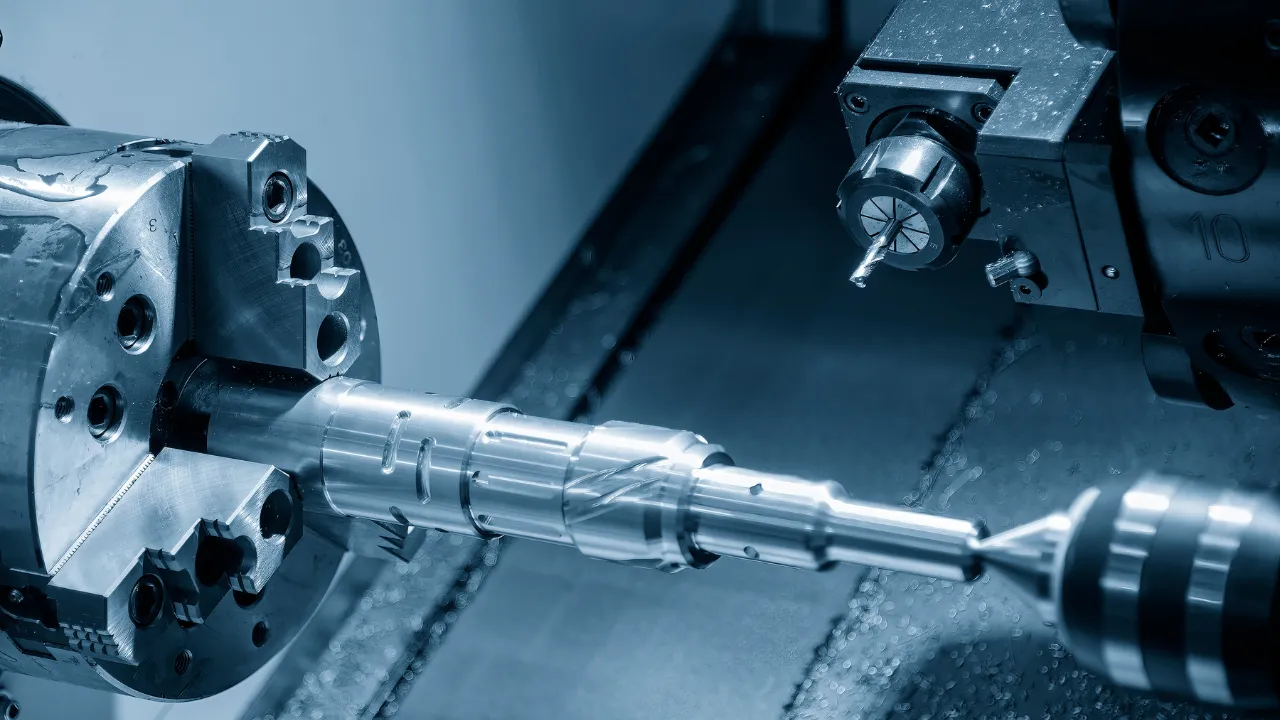

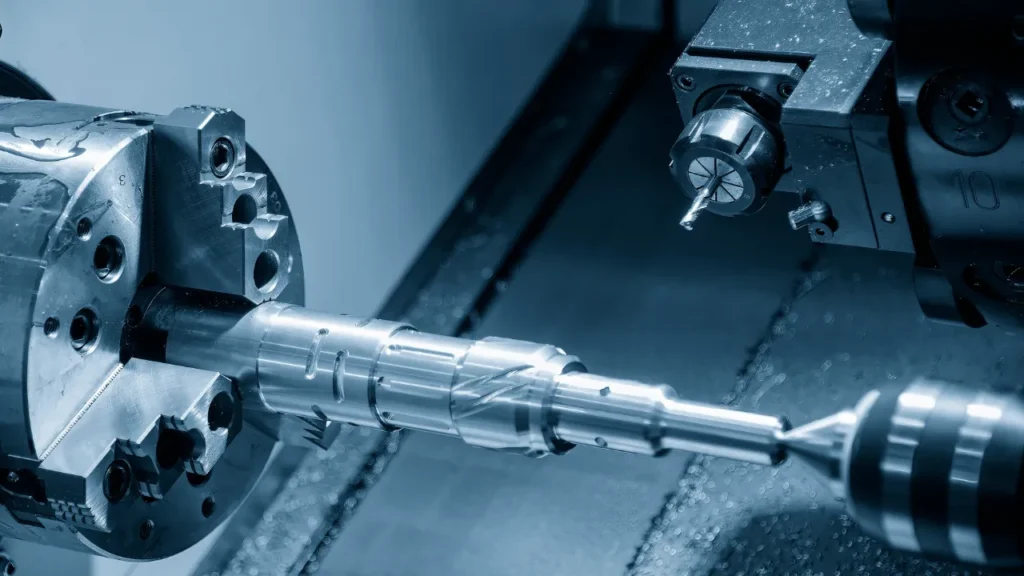

CNC Machining error refers to the degree of deviation between the actual geometric parameters (geometric dimensions, geometric shapes, and mutual positions) of a part after machining and its ideal geometric parameters.

The degree of conformity between the actual geometric parameters and the ideal geometric parameters after part processing is referred to as machining accuracy. The smaller the machining error, the higher the degree of conformity, and the higher the machining accuracy.

Machining accuracy and machining error are two ways of describing the same issue. Therefore, the magnitude of machining error reflects the level of machining accuracy. The primary causes of machining errors include the following:

1. Machine Tool Manufacturing Errors

The inherent accuracy of the machine tool sets the ceiling for the part’s precision.

- Spindle Rotation Error (Spindle Runout): This is the variation of the actual rotation axis relative to the ideal axis. It is caused by coaxiality errors, bearing wear, and spindle deflection.

- Guideway Error: The guideway is the datum for machine motion. Manufacturing inaccuracies, uneven wear, and poor installation lead to linear deviations.

- Transmission Chain Error: This involves the relative motion error between the start and end of the drive chain, often caused by gear wear or assembly inaccuracies.

2. Tooling Geometry Errors

Cutting tools inevitably wear down during the machining process, altering the part’s dimensions.

- Fixed-size Tools: For tools like drills or reamers, manufacturing errors directly impact the hole size.

- General Tools: For turning tools, while manufacturing error is less critical, the tool tip wear significantly impacts dimensional consistency.

3. Fixture Geometry Errors

The fixture’s role is to ensure the workpiece is correctly positioned relative to the tool and the machine. Any geometric error in the fixture translates directly into positional errors on the workpiece.

4. Positioning Errors

- Datum Non-coincidence Error: Occurs when the positioning datum used during machining does not align with the design datum on the blueprint.

- Inaccuracy in Positioning Pairs: Errors caused by the manufacturing clearance between the workpiece surface and the fixture’s locating elements. This typically occurs during batch adjustment processes.

5. Process System Deformation Under Force

- Workpiece Stiffness: If the part is thin-walled or slender, it may deflect under cutting forces.

- Tool Stiffness: A long, thin boring bar will vibrate or deflect more than a short, rigid tool.

- Machine Stiffness: The combined rigidity of joints, friction surfaces, and clearances within the machine assembly.

6. Thermal Deformation

Thermal expansion is a major enemy of precision, sometimes accounting for 50% of total error in large or ultra-precise parts. Heat sources include cutting friction and the machine’s internal motors and bearings.

7. Adjustment Errors

In every process, the operator or programmer must adjust the relative positions of the tool and workpiece. Since no adjustment is perfectly accurate, these human or system-controlled offsets introduce “Adjustment Error.”

8. Measurement Errors

Precision is only as good as the ability to measure it. Measurement errors stem from gauge inaccuracy, improper measurement methods, and environmental factors like temperature or human subjectivity.

9. Internal Stress (Residual Stress)

Internal stress exists within the material without external force. Once the material is machined, these stresses seek a low-energy stable state, causing the part to warp or deform over time, leading to a loss of original accuracy.