Blog

Company News, Industry Information, and more.

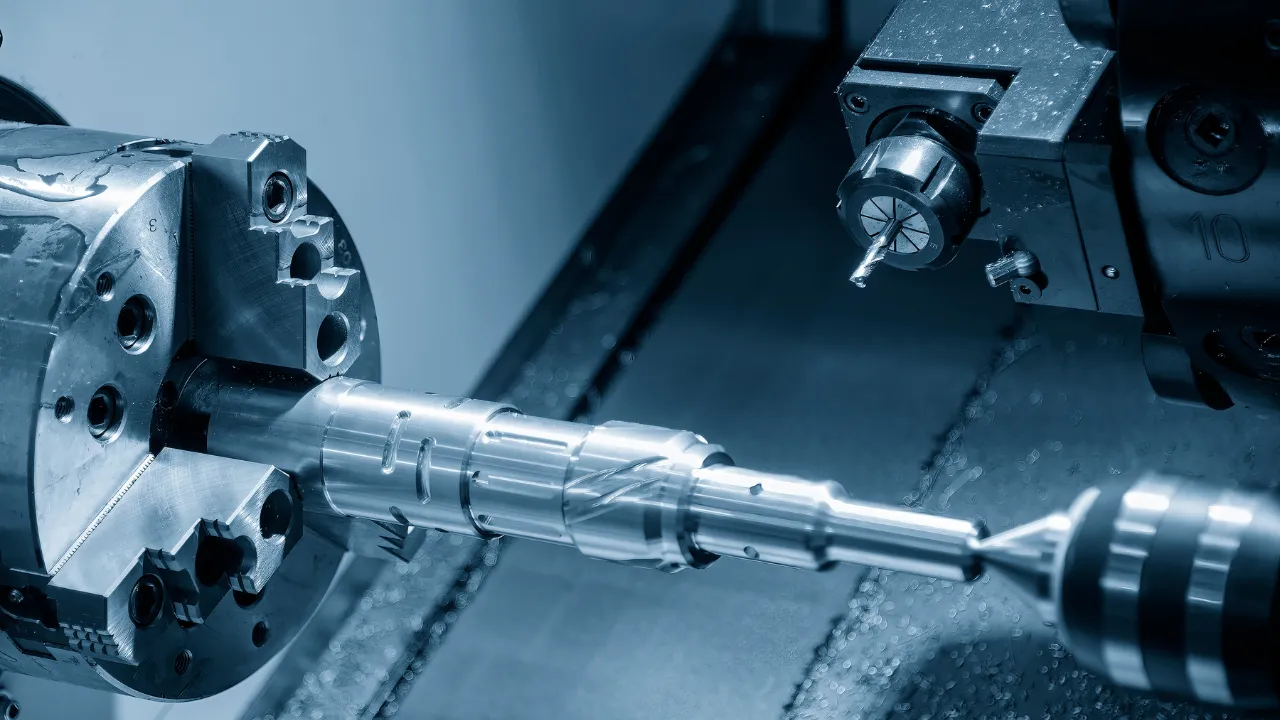

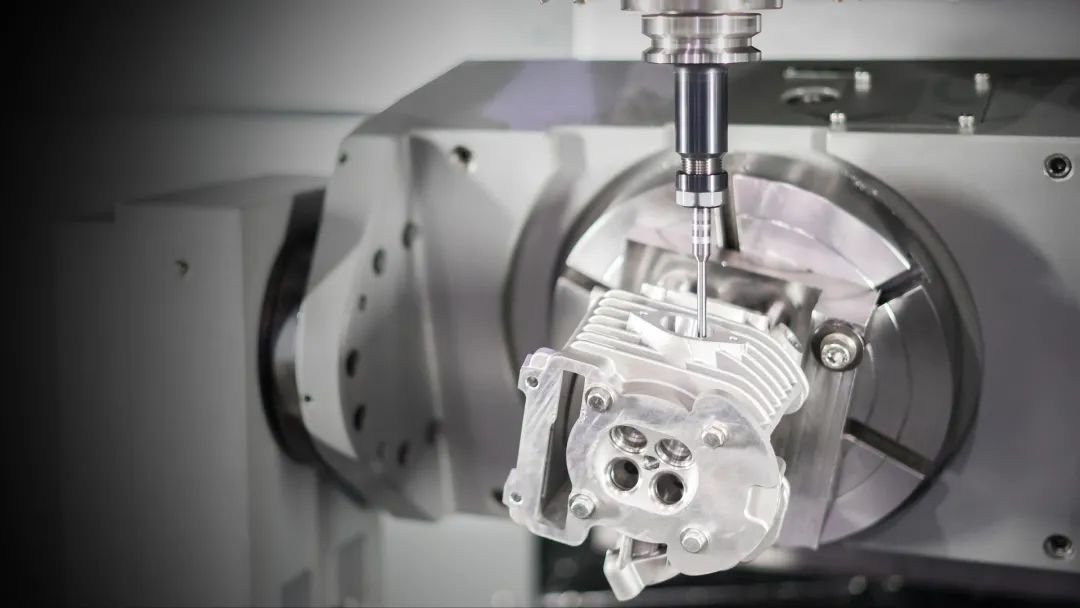

This article explains 9 major sources of machining errors, including machine tool inaccuracies, tool and fixture errors, positioning errors, force and thermal deformation, adjustment errors, measurement errors, and internal stress, helping engineers improve machining accuracy and consistency.

A comprehensive list of 42 machining process FAQs, from clamping methods and machining stages to error classification, fixture structure, and surface roughness control—helping engineers master key CNC machining principles.

Each process offers unique advantages in terms of material selection, precision, cost, and production speed. Understanding the strengths and limitations of these technologies helps manufacturers choose the most efficient and cost-effective path from concept to reality.

This article provides a detailed overview of the types and applications of heat treatment in CNC machining, from annealing to precipitation hardening, explaining how each process enhances the strength, hardness, and machinability of metal components.

This article systematically introduces cost control strategies throughout the entire process, from design to manufacturing, providing practical and comprehensive guidance.